BULLION BARS CASTING

MOQ : 1 Piece

BULLION BARS CASTING Specification

- Product Type

- BULLION BARS CASTING

- Power Source

- Electricity

- Operating Type

- Automatic

- Surface Treatment

- Coated

- Color

- Blue & White

- Warranty

- 1 Year

- Usage & Applications

- Industrial

BULLION BARS CASTING Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 2 Days

- Main Domestic Market

- All India

About BULLION BARS CASTING

BULLION BARS CASTING

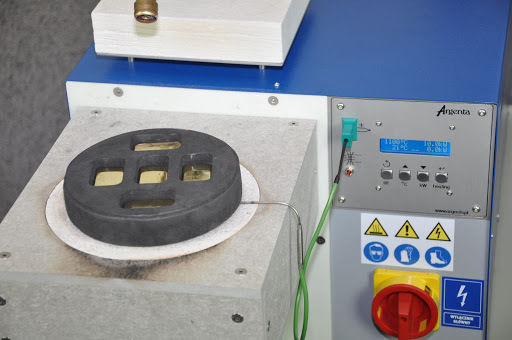

An induction furnace adapted for melting bullion bars of a precisely defined mass. The precisely weighed material is poured into forms of the desired shape and melted by the electromagnetic field in the shortest possible time. The temperature measurement takes place in the middle of the graphite mold and it is conducted by the K type thermocouple.

The graphite mold is placed manually on top of the inductor chamber, and the magnetic field has an impact from the bottom. After melting alloy, form stays in place until the metal clots.

The upper arrangement of the graphite mold of the use of a burner (propane-butane) to control the cooling of the molds and to create a reducing atmosphere.

The maximum size of the graphite mold is determined by the outer diameter of150mm and the height of 30mm. This means that we can make any size of the forms within these dimensions.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Vacuum Casting Machine Category

Vacuum Pressure Casting Machine

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Power Source : Electricity

Surface Treatment : Coated

Operating Type : Automatic

Usage & Applications : Industrial

Agatronic Vacuum Casting Machine

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Power Source : Electricity

Surface Treatment : Coated

Operating Type : Automatic

Usage & Applications : Industrial

Vacuum Induction Casting Machine

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Power Source : Electricity

Surface Treatment : Coated

Operating Type : Automatic

Usage & Applications : Industrial

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry